AlphaSorb® Wood Fiber Acoustic Panels

Return Policy: This product is non-returnable

Typical Shipping Lead Time: call for lead times

Product Description

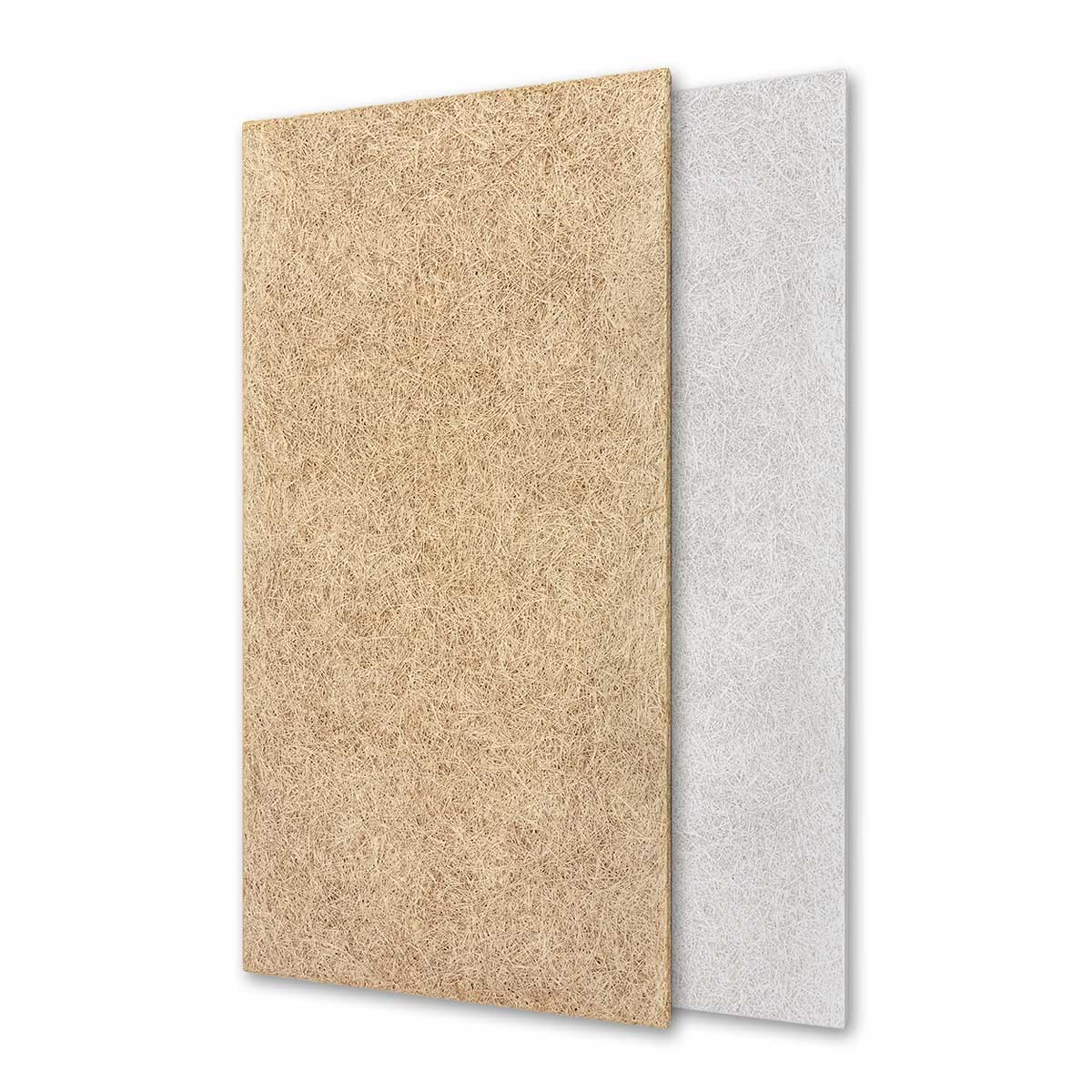

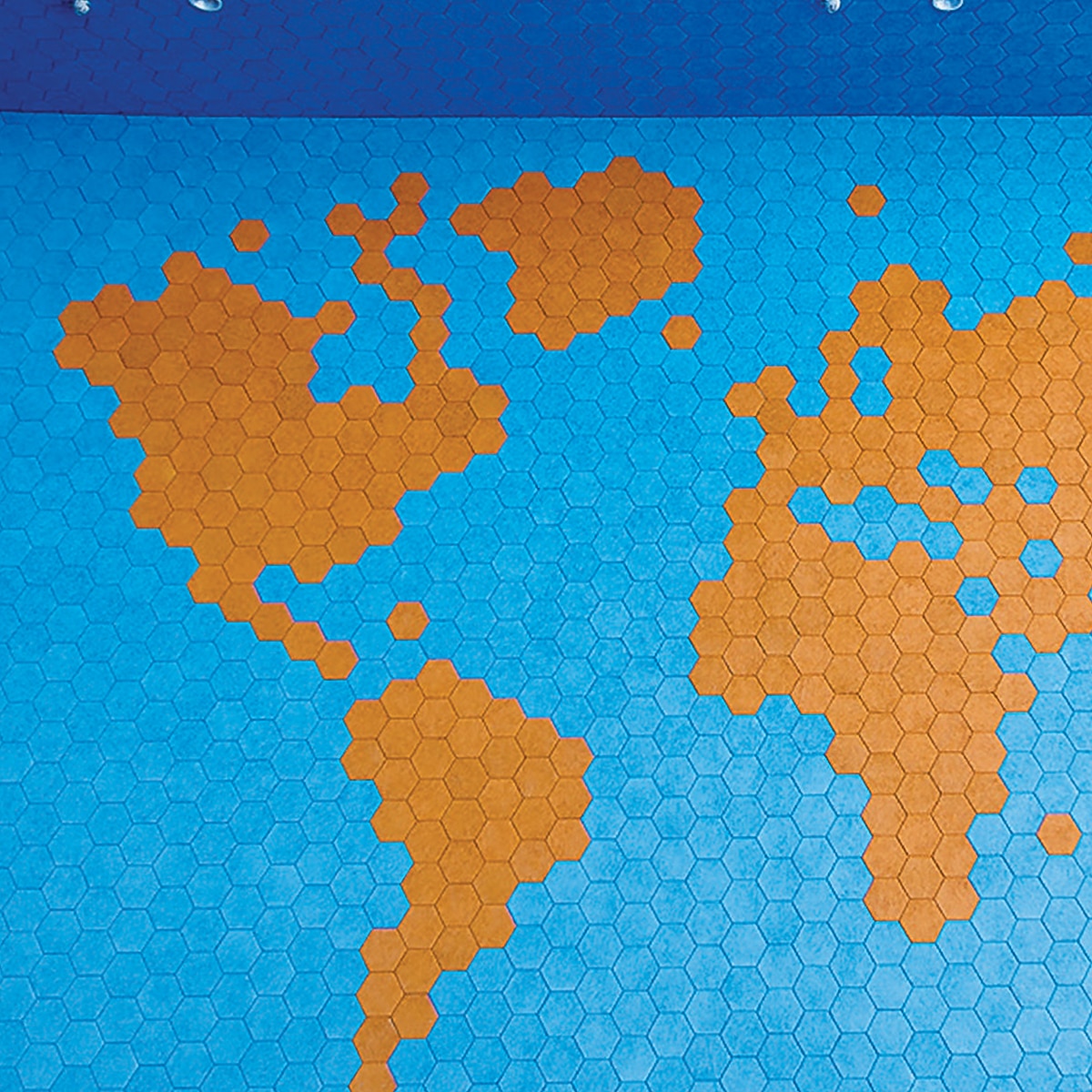

AlphaSorb® Wood Fiber Acoustic Panels are Eco-friendly, cost-effective acoustic panels for use in a wide range of wall and ceiling applications. The woven nature of the reinforced wood fiber core makes this an effective sound absorbing panel. This also allows for multiple applications of paint, without impacting acoustic performance. You can complement any room décor with white or natural colors or you can paint on site in any color you desire. Our Wood Fiber acoustic panels are available in a range of nominal sizes for direct to ceiling or wall mount applications.

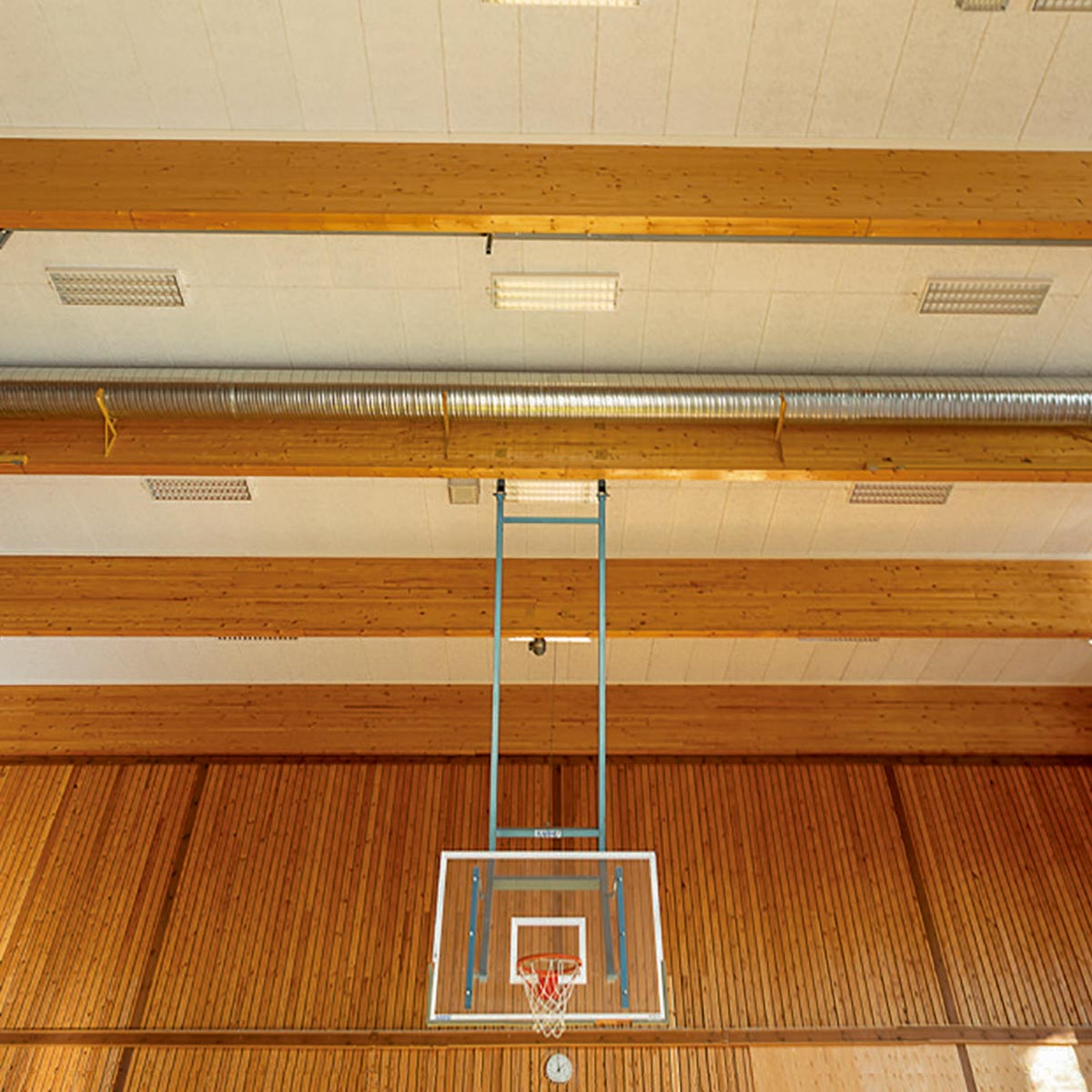

The wood fiber core of our Wood Fiber Acoustic Panels not only livens up a room with design variety, but reduces echo and reverberation for a better sounding environment. With optional edge designs, use wood wool fiber panels to transform the aesthetics as well as the acoustics of any interior space. There are multiple methods for wall or ceiling mounting, making his a versatile acoustical treatment. For best results, Wood Fiber acoustical panels are best spray painted on-site upon completion of installation.

AlphaSorb® Wood Fiber Acoustic Panels may be used for sound and noise control in a range of spaces including schools, civic centers, gymnasiums, classrooms, auditoriums, band rooms, restaurants, bars, entertainment venues, shooting ranges, manufacturing and industrial facilities.

Features

- Durable panels with consistent finish and color

- Faster lead times than competitor equivalents

- Cost effective over other solutions

- Low VOC (Volatile Organic Compounds)

- Mounts to walls or ceilings

- Ready to paint

Technical Information for AlphaSorb® Wood Fiber Acoustic Panels

- Sizes: 24″ x 24″, 24″ x 48″, 24″ x 96″ (call us)

- Thickness: 1″, 1 3/8″, 2″

- Core Construction: Small Strand Cementitious Wood Fiber Acoustical Board manufactured from wood fiber, cement & water

- Edge Detail: Square, Bevel

- Finish: Clear or White Primer, Custom Paint Color

- Intended Use: Sound absorbing panels for interior spaces to reduce echo and reverberation

- Weight: 2 pounds per square foot

- Fire Rating: Class 1 or A per ASTM E84

- Installation Methods:

- Direct to wall or ceiling with mechanical fasteners

- Direct attachment to furring strips, hat channel or drywall T-grid

- NRC: 0.45

| Sound Absorption (Hz) Type A Mount | ||||||

| 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

| 0.08 | 0.12 | 0.26 | 0.52 | 0.89 | 0.60 | 0.45 |