So, you want to know how to eliminate noise in an echo-y room and are wondering how to compare all of the many options that are out there. You aren’t alone. There are a ton of products out there claiming to do just that. It’s overwhelming, even for the contractor pros we work with. That’s why so many folks call us to discuss their situation and make sure they’re buying something that will actually solve their problem.

AlphaSorb® Fabric Wrapped Acoustic Panels in Whisper Fabric

We have a few competitors that sell low-cost acoustic panels made with a mineral wool core so it’s not uncommon for customers to ask me about the difference between mineral wool and fiberglass for sound.

Fiberglass insulation is made from sand and glass mixed with a polymer glue, which creates the distinct yellow color. The sand and glass are processed and mixed, with glue keeping everything together. It holds its shape and, once cut to size, simply needs to be wrapped in a protective cloth, which also makes it visually appealing. Overall, fiberglass is an efficient rigid material that provides convenient options for absorbing sound.

Mineral wool is made from a different material, although the process is often the same. This type of insulation is made from rock mixed with other materials. Manufacturers heat the rock and melt the material, which changes it into small fibers. The fibers are then spun to create a loose wool-like material, which is then placed one-over-another to create large sheets. Mineral wool is usually found between joists and studs, and it’s largely used for thermal insulation, not soundproofing.

Mineral wool is heavier; the final product, when packed into a frame, feels more like a solid mattress.

Each has unique advantages, as well as potential downsides. Understanding their differences can help you make the best choice for your specific space.

Mineral Wool vs. Fiberglass: Factors to Consider

Construction

The most important difference, at least as far as acoustic professionals, building managers, and installers are concerned, is the construction of mineral wool or fiberglass panels.

Mineral wool is a loose material; it doesn’t hold a rigid or semi-rigid shape like fiberglass. This means that mineral wool panels need to be built with a frame, which is then filled with the insulating material and finally wrapped in a fabric facing.

Contrast that with fiberglass, which is semirigid and holds its shape without a supporting frame. Fiberglass panels can be cut to shape, wrapped in a cloth exterior (which is class A fire rated and acoustically transparent), and placed wherever they are needed.

Framed vs. Frameless Fiberglass Panel

In the above image, the left is an example of a fabric-wrapped fiberglass acoustic panel and the right is a framed acoustic panel filled with mineral wool on the right. Both are 2” in width, while the frameless fiberglass is a 6 pound density absorber and the framed mineral wool is a 3 pound density absorber.

When considering the added weight of the frame, it is easy to see the advantages of selecting fiberglass over mineral wool for this application. The rigid frame does provide more protection to a mineral wool panel if it’s dropped or handled roughly, but a fiberglass panel is more lightweight which makes hanging them a breeze. Fiberglass panels can also be hung a number of different ways using impaling pins, rotofasts, or Z-clips.

Sound Absorption

At Acoustical Solutions, our company mission is to make every environment better by solving sound and noise control problems. So if you want to know why we recommend a frameless fiberglass panel, it boils down to its ability to absorb sound.

The sound absorption of a material is measured by its Noise Reduction Coefficient, (NRC). Typically, when a plywood frame is filled with mineral wool and wrapped in polyester fabric, the NRC of that panel is 0.95.

We use a 6 lbs/cubic foot, high density fiberglass in our fabric wrapped acoustic panels. Our panels are wrapped in a polyester fabric that’s adhered to the fiberglass with a water-based glue. The end result is a NRC of 1.0, about 5% better than mineral wool.

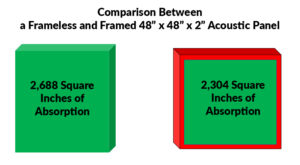

A frameless fiberglass acoustic panel absorbs sound on both the front face and the sides. It can even absorb sound on the back of the panel if there is an air gap between the wall and the panel. By contrast a framed mineral wool panel only absorbs sound inside the framed area. The frame itself actually reflects sound which detracts from sound absorption.

In the below comparison, you’ll note that the frameless acoustic panel has an extra 384 square inches of absorption, or 17.6%. This is a significant difference.

Cost

While overall cost should not be the only factor in your decision, I fully understand (and appreciate!) that everyone has a budget. Since fiberglass panels have more absorptive strength, you need fewer panels to achieve the same acoustic result. In addition to saving money by buying fewer panels, there is also savings in the cost to ship and install them.

Weight

Fiberglass is light and fluffy, and it has a composition that is more like dense cotton candy. Mineral wool, because it’s made from rock and stone, is much heavier. The added weight limits the potential applications for mineral wool, which makes it harder to use the material for mounted panels and ceiling tiles.

Cleanliness

Mineral wool is a loose material that must be packed into a frame or stuffed into a building cavity, such as the space between studs. Fiberglass is a compressed board, a single piece that holds its individual shape. Mineral wool is dusty and can spread particulates into the air, so fiberglass is generally considered the cleaner option.

Longevity

The overall longevity of fiberglass or mineral wool depends on how the material is used and to what conditions it is exposed. (High moisture or dry conditions, for example.)

That said, mineral wool has a reputation for longevity, but the loose material can also sag or shift. Fiberglass panels, because they are stiff, solid objects, do not have this issue and tend to hold up better over long periods.

Mineral Wool vs. Fiberglass for Sound: Which Should You Choose?

AlphaSorb® Fabric Wrapped Acoustic Panel Edge Styles – Square, Beveled, Mitered, Rounded (not available)

Mineral wool has a higher density, but because of its general nature (loose, dusty material) it requires a container of some sort to create panels. It typically costs more and has a heavier weight, which makes it both expensive and cumbersome.

Fiberglass, in contrast, is much more convenient. It holds its shape and can be cut into tailored panels, all without an additional frame. This makes it easier to use for a variety of purposes, including wall panels, ceiling tiles, and other areas where soundproofing is required. One example that many of my customers love is our AlphaSorb® Fabric Wrapped Acoustic Panel.

If you need more information, I’m always available to answer any questions related to mineral wool vs. fiberglass for sound. When you’re ready, I can help you select the right material for your specific room or building, and help soundproof all necessary walls.

Reach out to our experts today or give me a call at 800-782-5742 and let’s get started today!

To learn more about how Acoustical Solutions can solve your noise control problems, use our contact form, call one of our Acoustical Sales Consultants at (800) 782-5742, or visit us on the web at acousticalsolutions.com.