Not long ago, I worked with a customer who was transforming their spare room into a home theater. They had all the essentials—an oversized screen, surround sound speakers, and even reclining chairs. But there was one glaring issue: the acoustics. Dialogue was muffled, and loud action scenes sounded chaotic with all the echo bouncing around the room.

Their first thought was to make DIY acoustic panels to reduce the echo and improve sound clarity. While I admired their enthusiasm, I walked them through the challenges of building panels from scratch and explained how professional acoustic panels from Acoustical Solutions could save them time while delivering superior results.

In the end, they decided on a hybrid approach: a few DIY panels for decorative purposes and professional-grade panels for the heavy lifting. The result? A cinematic sound experience that truly brought their theater to life. Let’s explore how you can achieve the same for your space—whether through DIY or professional acoustic solutions.

Why Acoustic Panels Matter

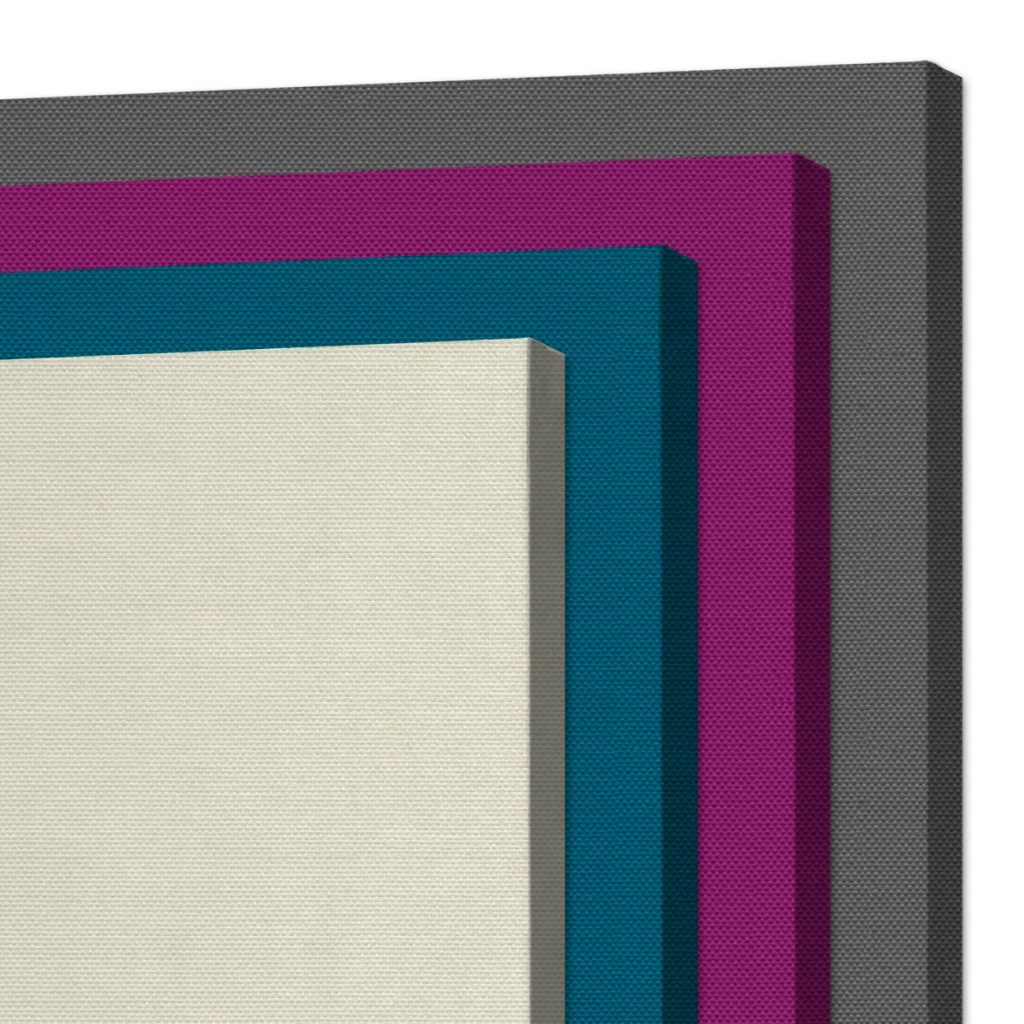

AlphaSorb® Fabric Wrapped Acoustic Panels in Whisper Fabric

Acoustic panels are essential for controlling sound in a room by reducing echoes, reverb, and noise reflections. They create a balanced acoustic environment that improves audio clarity for activities like recording, gaming, or watching movies. Whether you’re working in a home theater, studio, or office, acoustic panels are a must-have for sound quality and comfort.

DIY Acoustic Panels: The Pros and Cons

Before diving into a DIY project, it’s important to understand the benefits and limitations of building your own acoustic panels.

Pros of DIY Acoustic Panels

- Cost Savings: DIY panels can be more affordable if you already have tools and materials.

- Customization: You can choose your own fabrics, sizes, and designs to match your space.

- Creative Satisfaction: There’s a sense of pride in building something yourself.

Cons of DIY Acoustic Panels

- Performance Limitations: Achieving the same level of sound absorption as professional panels is challenging without proper materials like Owens Corning 703 or rockwool.

- Time-Consuming: Cutting, assembling, and covering panels takes time and effort.

- Durability Concerns: Poor construction or materials may lead to sagging, fraying, or reduced effectiveness over time.

- Fire Safety: Professional panels, like those from Acoustical Solutions, meet fire safety standards—something DIY panels often lack.

The Reality of DIY Acoustic Panels

DIY acoustic panels are a good option for those who enjoy hands-on projects and don’t need top-tier performance. However, many customers discover that the cost savings don’t always outweigh the time and effort required. For example, fabric choices can affect absorption performance, and poorly sealed frames may compromise the panel’s durability.

Acoustical Solutions Advantage

Our AlphaSorb® Fabric Wrapped Acoustic Panels are professionally tested and crafted for optimal sound absorption. With ready-to-mount designs and fire-rated materials, they save you time and deliver superior results.

How to Build DIY Acoustic Panels

For those determined to try DIY, here’s a quick guide:

Materials Needed

- Frame: Pine wood or pre-made canvas frames.

- Absorptive Material: Rockwool, Owens Corning 703, or acoustic foam.

- Fabric: Breathable options like burlap or polyester.

- Tools: Staple gun, screws, adhesive spray, saw, and mounting hardware.

Steps

- Build the Frame: Cut wood to size (2’x4’ is standard) and assemble a rectangular frame using screws or nails.

- Add the Absorptive Material: Cut rockwool or foam to fit snugly inside the frame.

- Cover with Fabric: Stretch breathable fabric over the frame, ensuring it’s tight and secure with staples or adhesive.

- Mount the Panels: Use brackets or adhesive strips to mount the panels on walls or ceilings.

Acoustical Solutions: A Better Alternative

AlphaSorb® Fabric Wrapped Acoustic Panel Edge Styles – Square, Beveled, Mitered, Rounded (not available)

If the DIY process sounds overwhelming or you want guaranteed results, consider professional acoustic panels from Acoustical Solutions. Here’s why our panels stand out:

- Superior Performance: Our AlphaSorb® Panels are engineered for maximum sound absorption, reducing echoes and reverb far better than most DIY options.

- Durability: Built with high-quality materials, our panels are designed to last in demanding environments.

- Fire-Rated Safety: All our panels meet fire safety standards, making them ideal for both residential and commercial spaces.

- Easy Installation: Panels come ready to mount, saving you time and effort.

Common Questions About DIY Acoustic Panels

Are DIY panels as effective as professional panels?

DIY panels can work for basic sound absorption, but professional panels offer better-tested and more consistent results.

What materials should I use for DIY acoustic panels?

Rockwool or Owens Corning 703 are highly recommended for their sound absorption properties.

Can I mix DIY and professional panels?

Absolutely! Many customers use DIY panels for aesthetic accents and professional panels for high-performance needs.

The Best Choice for You

Cedia Honored Home Theater

Building DIY acoustic panels can be a rewarding project, but it’s not always the best solution for everyone. If you’re looking for high-quality, durable, and easy-to-install options, Acoustical Solutions offers a wide range of professional acoustic panels to meet your needs.

Ready to transform your space? Explore our catalog or contact us for expert guidance on acoustic solutions. Whether you’re building your own panels or seeking professional-grade performance, we’ve got you covered.

To learn more about how Acoustical Solutions can solve your noise control problems, use our contact form, call one of our Acoustical Sales Consultants at (800) 782-5742, or visit us on the web at acousticalsolutions.com.