AlphaSorb® Anechoic Foam

Product Description

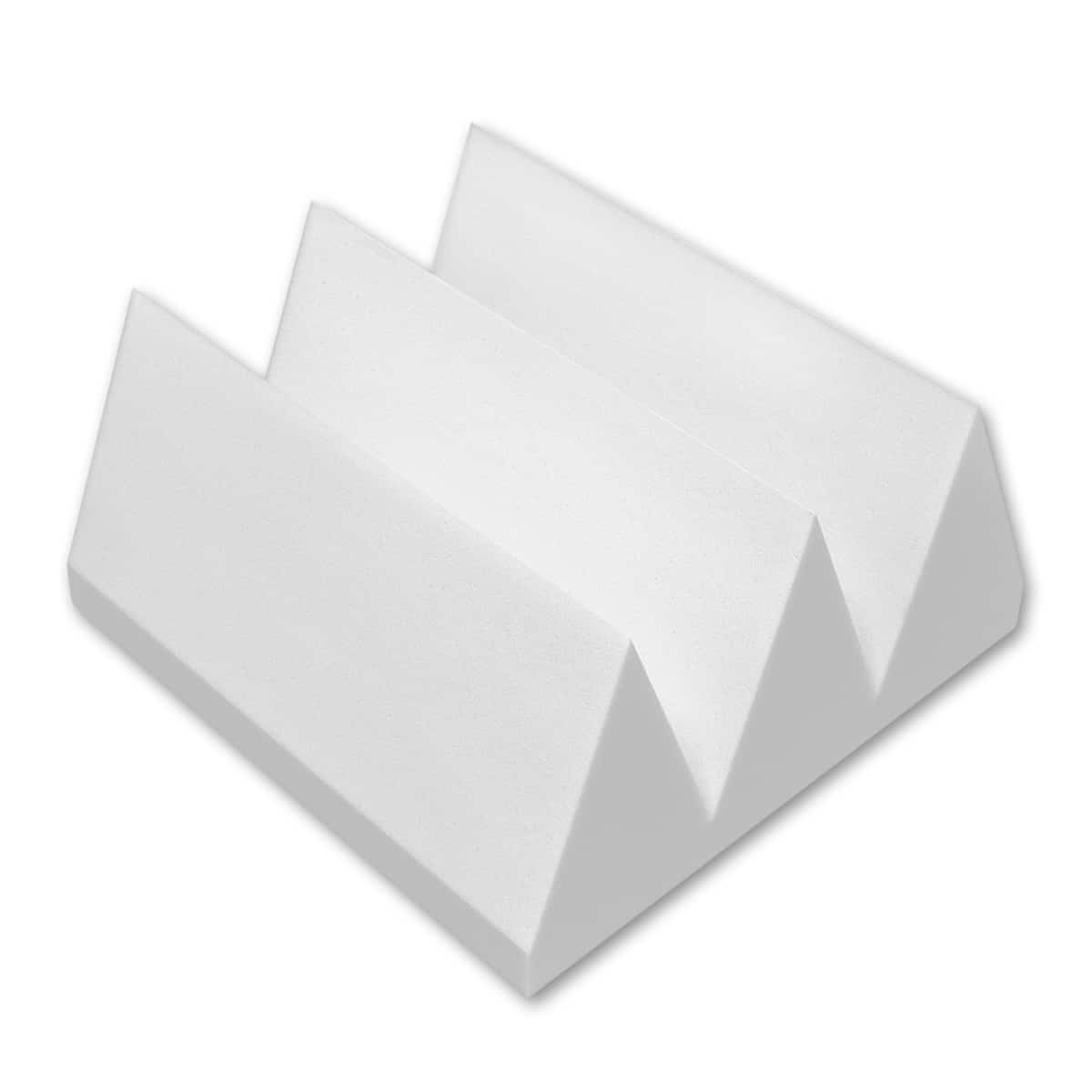

AlphaSorb® Anechoic Foam (formerly AlphaSorb® Max Wedge Foam) provides maximum absorption and is ideal for testing rooms, research facilities, and anechoic chambers along with massive spaces like auditoriums, arenas, and industrial buildings for OHSA compliance. This acoustic foam can dramatically improve the accuracy of sound measurements by eliminating bounce-back sounds such as echo, feedback and resonance. The deep wedge pattern and 6 in. thickness offers maximum absorption and increased mid to low frequency response with an impressive Noise Reduction Coefficient (NRC) of 1.25.

The bold, geometric design of this 3-point anechoic wedge can be used in suspension systems or adhered directly to walls in a variety of patterns to create visual interest and maximize the acoustical performance. Lightweight and easy to install, the anechoic wedges are the perfect solution to your demanding sound absorption applications. AlphaSorb® Anechoic Foam may be manufactured in custom sizes to specification for testing chambers. Please contact us with your project requirements.

NOTE: This product has been transitioned to a new manufacturing process. Material may vary slightly to previously ordered material.

Applications

- Testing Facilities

- Anechoic Chambers

- Industrial Applications

- Broadcast and Recording Studios

Features

- Reduces echo and reverberation

- Improves speech intelligibility

- Low frequency absorption

- Exceptional acoustical and thermal properties

- Mold-resistant, fire-retardant

Technical Information for AlphaSorb® Anechoic Foam

- Size: 1′ x 1′

- Thickness: 6″, 8″

- Material: Open-cell melamine-based foam

- Intended Use: Interior, sound absorption

- Finish:

- Natural Grey

- Natural White

- Coated (Custom Order, please call)

- Density:

- Light Grey: 0.56 +/- 0.09 lb / sq ft

- White: 0.47 +/- 0.13 lb / sq ft

- Service Temperature: -40 deg. F to 350 deg. F

- Fire Rating: Class 1 or A per ASTM E84

- NRC: (6″) 1.25, (8″) 1.35

| Sound Absorption (Hz) | |||||||

| Thickness | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

| 6″ | 0.58 | 1.09 | 1.34 | 1.31 | 1.32 | 1.34 | 1.25 |

| 8″ | 0.67 | 1.17 | 1.45 | 1.41 | 1.42 | 1.36 | 1.35 |

Installation Method

- These panels can easily be mounted to any wall or ceiling surface with water-based construction adhesive.

- Installation is best done at the end of the construction project.

- Use clean gloves to prevent soiling material.

- Melamine foam is fragile and should be handled with care.

- Maintain uniform temperature of minimum 60° F and maximum humidity of 40% prior to, during and after installation.

- Do not install material of unacceptable quality.