Digital sound wave shapes.

I thoroughly enjoy taking calls from customers seeking to soundproof their home theaters, music rooms, and offices. It’s such a treat when we can assist in providing the perfect acoustic setting for such individual projects; Although these projects are typically “fun” in the sense that they’re hobbyist endeavors, soundproofing is serious business, as my commercial customers know all too well.

A recent customer called to get my thoughts about meeting the strict acoustic building codes for a massive multifamily build that his firm was undertaking. While such building codes are not new and the customer and his team were already familiar with the standard building tactics to meet them, he decided to reach out to me to get my thoughts as an acoustic expert as to how they could achieve their goals better with the latest in new material technologies and understanding. This is what I mean by serious business, and how exciting for the opportunity to apply the best of modern soundproofing to a huge commercial project. We spoke about the materials they were considering for the wall assemblies, how they planned to layout the individual units in the building, and what they could do to reach the needed STC 50 sound rating to meet code. I’m proud to say we were able to provide newer solutions that, across such a large build, would also save them material and labor costs while meeting their goals.

In this article, I will unfold what is meant by the STC 50 rating as it applies to building codes and explore the best modern strategies and materials to meet STC 50 and beyond.

The Basics of Soundproofing and the STC rating

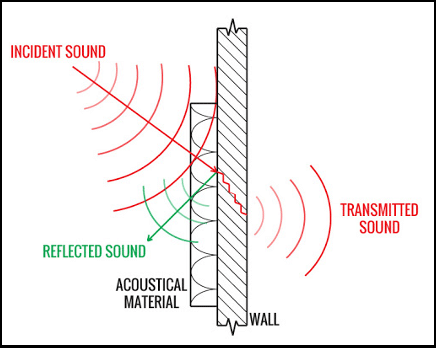

Soundproofing is often confused with sound control and the most important aspect of acoustics is understanding the difference. A more descriptive synonym for soundproofing is sound blocking, because that is what we’re trying to do: block sound.

For example, a movie theater needs to employ soundproofing so that the loud sonic experience stays within that single theater and doesn’t impose itself on adjacent theaters. The same goes for radio broadcast studios and music studios: we apply soundproofing to the walls, ceiling, floors, doors, and windows so that the sound cannot disturb others. Equally important, the same soundproofing will prevent outside noise from entering and disturbing what’s happening within.

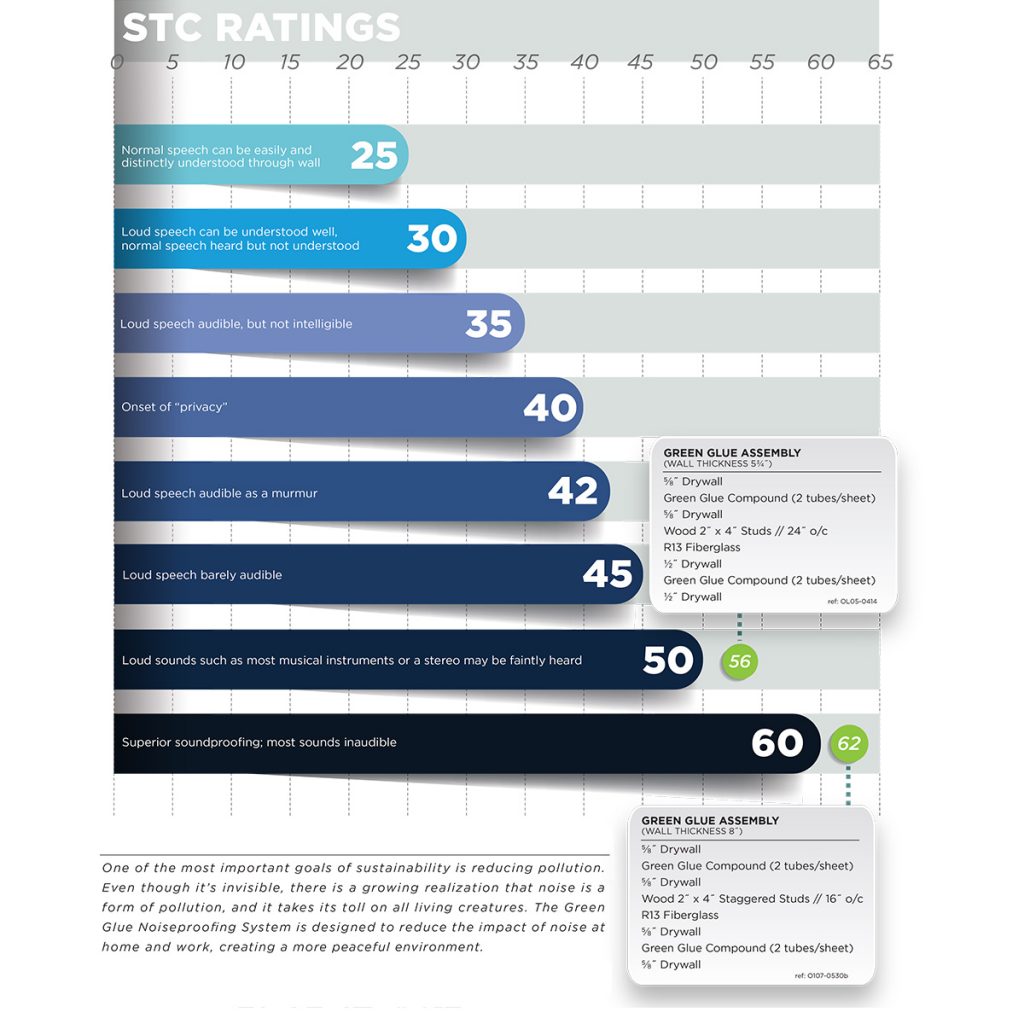

How we determine levels of soundproofing is through the Sound Transmission Class rating, or STC rating. In short, the STC rating calculates the effectiveness of materials to reduce sound transmission between rooms and represents the amount of decibel reduction. The higher the rating, the more effective the material assembly is at blocking sound.

The STC rating is used commercially as part of building codes to set a minimum soundproofing standard in multifamily structures in order to acoustically isolate units from one another. At this level of construction, it’s critical to have a uniform solution to achieve the desired acoustical outcome across hundreds or even thousands of units in such a way that optimizes material and labor costs.

Understanding Commercial Soundproofing and Meeting Code

Sound Absorption and Transmission

When it comes to building commercially, notably multifamily structures, soundproofing is critical because we want to acoustically isolate each unit so that voices and other sounds do not intrude upon one another. Thankfully, this is part of building codes so the want becomes a need. In effect, it’s not a great investment to spend millions of dollars on a multifamily structure where tenants complain that they can hear one another because of acoustically shoddy wall assemblies that lack proper soundproofing. That will lead to turnover, which is a headache that spirals over the years and decades of the structure’s lifespan.

To avoid this, the International Building Code (IBC) IBC 1206.2 and IBC 1206.3 dictate that airborne and structure-borne sound must meet a minimum lab-tested STC rating of 50. Meeting at minimum STC 50 means that wall assemblies will be able to significantly reduce sounds like TVs, music, talking, and laughing so that each individual unit will be acoustically sealed from one another, to provide a pleasing environment that renters and/or owners respect and desire.

That’s the easy part, understanding the STC 50 target and why we meet it. The challenging part is selecting the right materials and assemblies for a massive structure to meet these demands and not go over budget. Thankfully, improved building strategies and modern materials exist to meet this demand and help investors and builders achieve these goals in an optimized fashion.

The Two Keys to Meeting STC 50: Mass and Flexibility

Before getting to my top strategies to achieve STC 50, let’s look at the two basics of soundproofing: mass and flexibility.

Mass

As mentioned, with soundproofing we are trying to block sound. I like to think about it like blocking arrows with a shield. If you hold up a t-shirt, that arrow is coming right through! If you hold up a shield of wood, the arrowhead might pop through, but the arrow will be stopped. If you hold up a shield of concrete, that arrow isn’t coming through at all! The difference in these materials is their mass, or more specifically, the density of the material based upon the arrangement and number of their atoms.

Put simply: the more dense a material, the more it will block sound. This is why utilizing concrete is much more effective at blocking sound than a room with wooden studs covered by drywall.

Flexibility

Because soundwaves are more complicated than arrows, there is a second part of this puzzle to understand. No matter wood or concrete, the soundwaves will penetrate. How flexible the assembly is will be the final determination of how soundproofed the assembly will be. Here is a simple example using air gaps:

A 2-foot concrete wall will transmit more sound (have a lower STC rating) than two 12” concrete walls with a small air gap between them. Differentiating the medium – concrete to air to concrete – further erases the energy of the soundwave while with the 2-foot wall, more energy will vibrate through to the other side.

While this is a simple example to understand the way sound waves travel, a more pertinent example is the difference between 20 and 25 gauge steel studs. While 20 gauge studs have more mass, they are less flexible, which means that utilizing 25 gauge steel studs actually increases the STC rating (by as much as 4-7 points). Consider how many steel studs need to be utilized in a large building and we quickly see how many costs are saved by understanding the interplay of flexibility and mass.

Now, let’s look at the best strategies to achieve STC 50 and higher:

5 Strategies to Achieve STC 50 and Above

1. Utilize Steel over Wood for Studs

Typical builds utilize studs and drywall for wall assemblies. When comparing the two materials, steel has better flexibility than wood, so opting for steel studs means an increase in the STC rating right out of the gate. As mentioned above in our discussion about mass and flexibility, selecting 25 gauge steel studs is better than 20 gauge steel studs because the flexibility of 25 gauge offers more soundproofing capability than the added mass of 20 gauge. This also translates to cost savings since 20 gauge studs are slightly more expensive, which adds up significantly over a large project.

2. Increase the Depth of Studs

Building upon the flexibility differences of steel and wood, adding additional depth to the steel studs creates more flexibility and gains in STC rating points. For example, the difference between a 2×4 and a 2×6 wood stud in terms of flexibility is insignificant because of the properties of wood. However, because steel is more flexible, extending 3 ⅝” steel studs to 6” improves flexibility of the assembly to allow for more soundproofing.

3. More Space Between Studs

When working with steel studs, a final strategy to further improve the flexibility of the wall structure is to provide a larger gap between the studs. Instead of 16” on center, 24” on center will better harmonize with steel’s inherent flexibility and offer a further reduction in the ability of sound to transmit through the wall.

4. Soundproofing Membranes

Now that we have the bones of the wall assembly optimized for reduced sound transmission thanks to the correct size and placement of steel studs, it’s time to complete the wall. This is typically done with drywall, and too often we again think that more mass means more gains in the STC rating. The gains offered by doubling up layers of drywall is minimal (unless combined with Green Glue Noiseproofing Compound ), and doing so is inefficient as it at least doubles costs and further reduces square footage.

A much better solution is to apply the single layer of drywall with a soundproofing membrane that separates it from the studs. I love the capabilities of the AudioSeal® Mass Loaded Vinyl (MLV) Soundproofing Barrier. The product is dense and offers significant reduction in sound as well as providing more flexibility to the wall assembly as a whole.

5. Further Decoupling with Resilient Clips

To maximize flexibility and reach an outstanding STC 50+ rating, I suggest further decoupling the wall by the addition of resilient clips. This creates an air gap layer between the drywall and the steel studs. When used in concert with Green Glue Noiseproofing Compound and AudioSeal® Mass Loaded Vinyl (MLV) Soundproofing Barrier, this assembly is unmatched at blocking sound when weighed against costs.

Work with the Best for Achieving STC 50 and Higher with Acoustical Solutions

Hopefully it’s been apparent in this article, but I truly love soundproofing and helping customers no matter their situation meet their goals.

Whether you’re looking to soundproof a bedroom for a new podcast or want to provide an optimized, cost-effective plan for wall assemblies to meet building codes for commercial structures, I’m happy to jump on a call and explain the best that modern soundproofing products and strategies can offer.

Reach out today and let’s explore your unique situation and find the best acoustical solutions possible!

To learn more about how Acoustical Solutions can solve your noise control problems, use our contact form, call one of our Acoustical Sales Consultants at (800) 782-5742, or visit us on the web at acousticalsolutions.com.