AudioSeal® Mass Loaded Vinyl (MLV) Soundproofing Barrier

Product Description

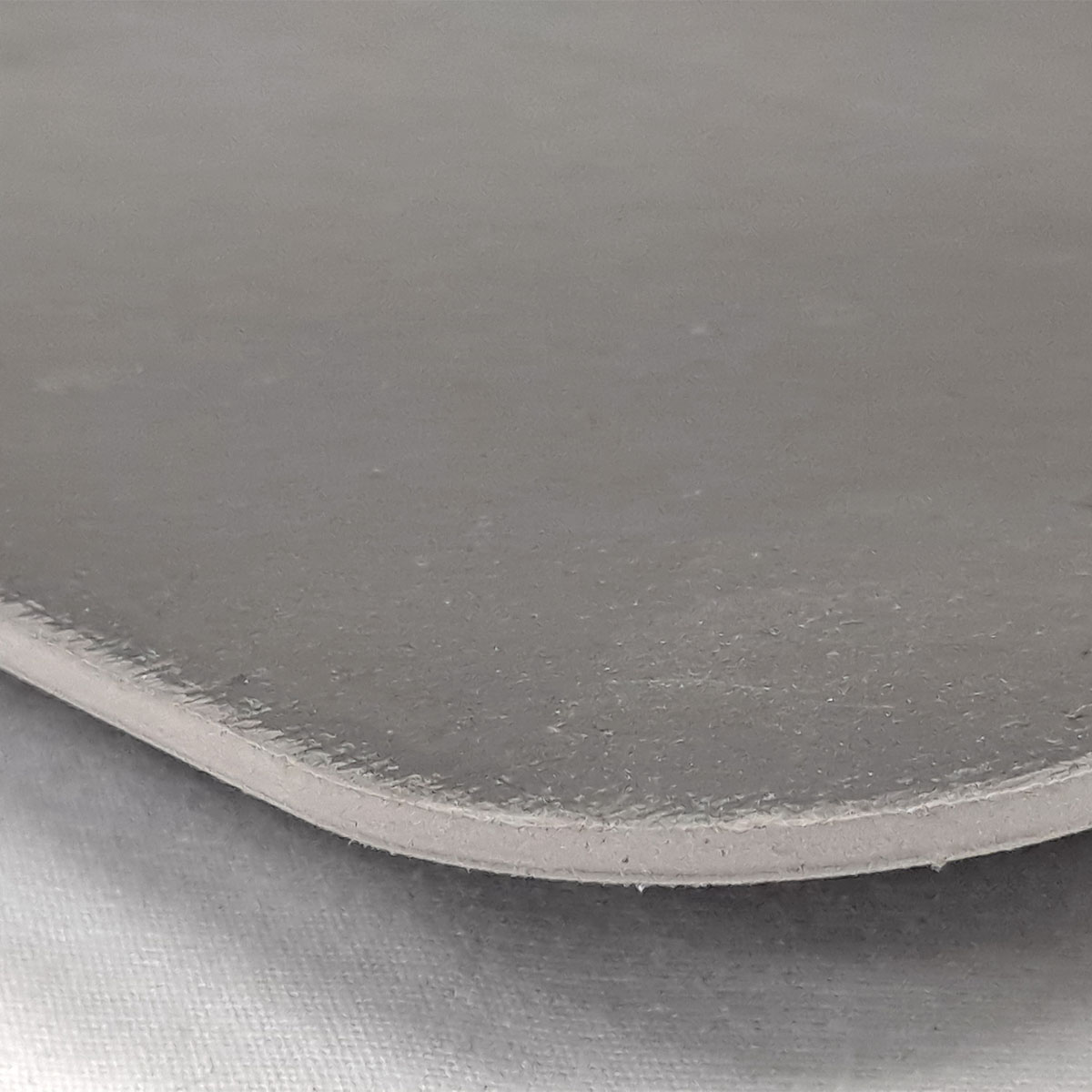

AudioSeal® MLV Soundproofing Barrier is an environmentally-safe mass loaded vinyl. It is very dense, weighing 0.6 to two pounds per square foot, and used to reduce the amount of airborne sound transmitting through walls, floors, and ceilings. It can be added to various construction assemblies to increase the STC (Sound Transmission Class) of the structure. This product is non-reinforced for wall and ceiling installations. It is commonly used in new construction when sound control is a requirement, or in renovations to correct noise problems in existing spaces.

Unlike PVC mass loaded vinyl, which emits VOCs as it hardens over time, AudioSeal® MLV Soundproofing Barrier is non-toxic. It is made from POE (polyolefin elastomer) which does not contain plasticizers or unsafe chemicals and doesn’t pose a health risk if it’s burned. AudioSeal® MLV Soundproofing Barrier is 100% recyclable and qualifies for LEED credits.

Application of AudioSeal® Mass Loaded Vinyl

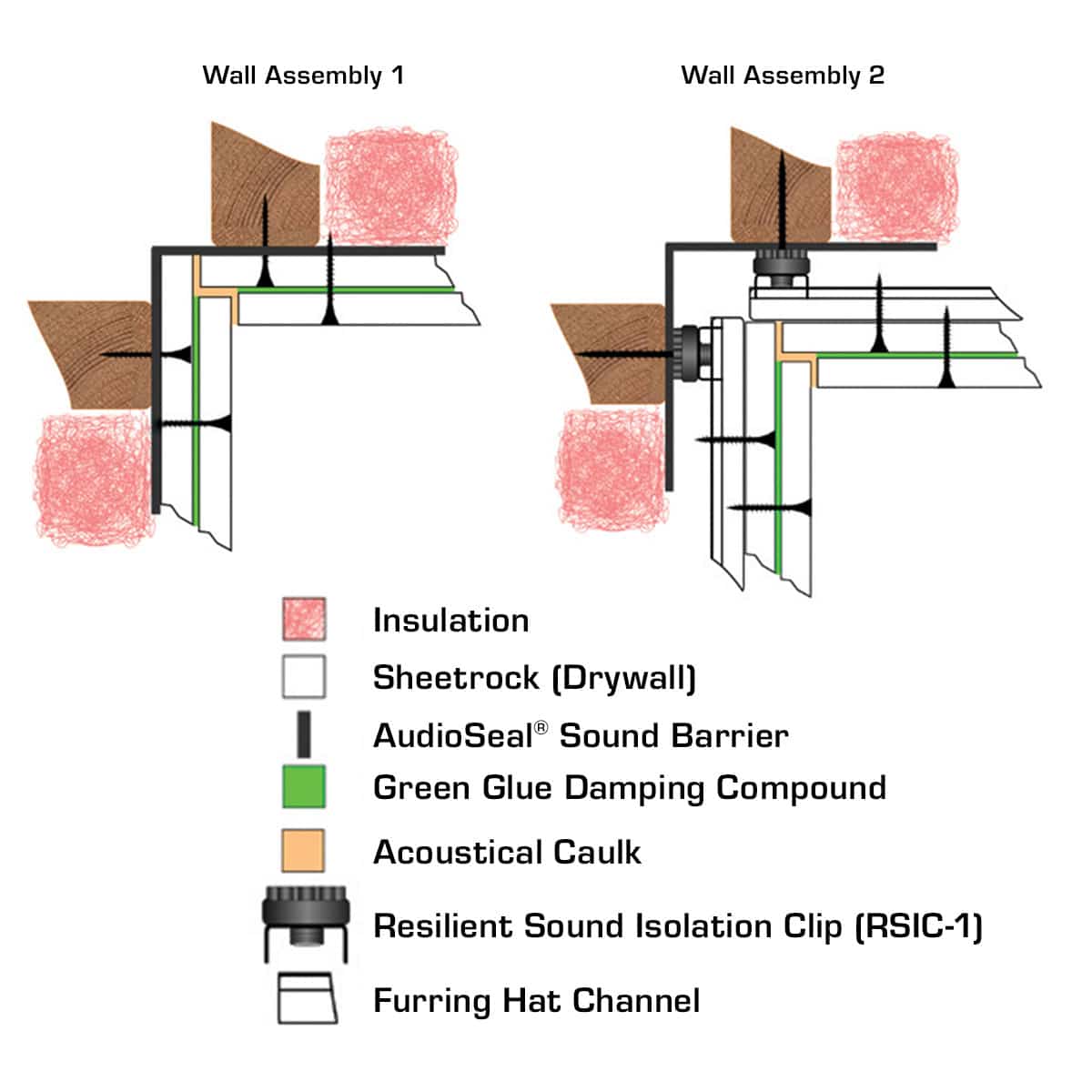

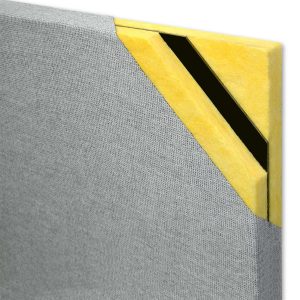

AudioSeal® MLV is tear-resistant, yet easy to cut with a utility knife. Usually installed directly to the studs or joist,. Often, mass loaded vinyl sound barriers are used in combination with other materials for robust soundproofing. Combining MLV with layers of sheetrock, Green Glue Noiseproofing Compound, and resilient clips and channels improves the sound transmission class of the complete assembly.

Our product is available in 10′, 15′, 25’ and 30′ lengths and either 48″ or 54″ widths to provide the best utilization for your project.

AudioSeal® Mass Loaded Vinyl Notes

- This product is not recommended for permanent exterior installation where exposed directly to ultraviolet light (sunlight).

- We recommend using seam tapes incorporating acrylic adhesives with this product. A suitable product is T-Rex Duct Tape, available at many hardware, big box, and building supply stores.

Technical Information for AudioSeal® MLV Soundproofing Barrier

- Roll Widths: 48″, 54″

- Roll Lengths: Various lengths up to 30′

- Thickness: 1/16″ (0.6 lb/ / sq. ft.), 1/8″ (1 lb. / sq. ft.), 1/4″ (2 lb. / sq. ft.)

- Color: Black

- Sold by: The Roll

- Type: Non-reinforced

- Weight: 0.6lb. / sq. ft. (1/16″), 1 lb. / sq. ft. (1/8″), 2 lb. / sq. ft. (1/4″)

- Tear Strength: 70 PSI

- Working Temperature: 32 deg. F to 150 deg. F

- Ultimate Elongation: 110%

- STC: 22, 26, 32

| Sound Transmission Loss (Hz) Non-Reinforced Barrier |

|||||||

| Weight | 125 | 250 | 500 | 1000 | 2000 | 4000 | STC |

| 0.6 lb. / sq. ft. | 9 | 14 | 17 | 23 | 28 | 32 | 22 |

| 1 lb. / sq. ft. | 14 | 16 | 21 | 27 | 29 | 47 | 26 |

| 2 lb. / sq. ft. | 16 | 22 | 26 | 32 | 35 | 40 | 32 |

Additional Stock Locations

In addition to shipping direct to you, AudioSeal® is also available for local pick up or delivery at the following additional locations. Call for delivery/pick-up arrangements and pricing.

- Foundation Building Materials Brooklyn, NY 718-388-6465

Frequently Asked Questions

In its base form, MLV is a thin (typically 1/8-in or 1/4-in thickness) sheet of vinyl that is infused with Calcium Carbonate (non-toxic & very dense) to add weight to such a thin product. What that means is the 1/8-in thick MLV weighs 1 lb. per square foot and the 1/4-in thickness comes in at a whopping 2 lbs. per square foot.

No matter the type of sound(s) one needs to block, the first two keys in sound blocking must be implemented: adding mass and total coverage. Mass loaded vinyl takes care of both.

The mass and suppleness of MLV offer effective sound-reducing abilities, and it’s relatively easy to apply. MLV is typically attached to joists or studs covering the entirety of a new wall or ceiling assemblies before being finished with drywall. Because of its thin “thickness”, it’s a great way to add more mass to assemblies.

Also, by installing it directly to the joists/studs, it remains somewhat limp against the inside of the joists/studs. This is called “limping” or “limped mass”. Limped mass makes the assembly more effective with some larger sound waves because it allows some “give” to ensure optimal soundproofing performance.

Think of it this way: in baseball, the foul ball net hangs loosely. This way, when a foul ball is hit into it, the net “gives” or moves with the ball, absorbing the ball’s energy. If the net were tight or rigid, the ball would bounce right back into the infield. It’s the same with sound waves and limped MLV.

MLV works by adding mass to a structure, which helps to block sound waves. The density of the material prevents sound from passing through it, effectively reducing noise transmission. It’s particularly effective at blocking low-frequency sounds, which are often the most difficult to mitigate.

Mass loaded vinyl can be attached to walls, ceilings, floors and windows in residential and commercial spaces to block out most everyday noises, like conversation, music and even traffic noise. MLV is a cost-effective solution to a variety of noise issues. As a DIY soundproofing option, MLV is one of the best.

MLV is typically attached to joists or studs, followed by covering seams and joints with acoustic caulking or barrier tape. Once sound caulking is applied, seams are sealed with tape to ensure optimal performance.

MLV is very easy to work with, so if you’re experienced and comfortable with DIY projects, you can save a significant amount of money by installing it yourself, particularly if you have a large area to cover. We recommend one to two assistants for most projects.

To install, you’ll need a tape measure, straight edge, staple gun, caulking gun and utility knife. Check out our installation video for an explainer of the full installation process:

Yes. Our mass loaded vinyl is non-toxic. Still, we recommend wearing protective gear when cutting and installing MLV to avoid inhaling dust or particles.

Not necessarily. As an alternative, you can use a stud finder to locate the studs behind the existing wall, mark them with a line, and drill vertical furring strips into the stud. Furring strips are thin, strips of wood used to level or raise surfaces.

From there, attach the MLV Soundproofing Barrier to the furring strips and add another layer of sheetrock over the barrier. Then add a thin layer of insulation. As with traditional MLV installation, make sure to caulk all the seams and gaps in the new layer of sheetrock to ensure optimal soundproofing.

This is not recommended. Mass Loaded Vinyl works best when it can move or vibrate in a three-dimensional space to absorb the energy of sounds. In the science of acoustics, this is referred to as a “Limp Mass Barrier.” Attaching MLV directly to sheetrock reduces its effectiveness, as it restricts the movement of the sound barrier. However, we do have a product – Green Glue – for this specific type of application.