The desire for mechanical room soundproofing is one I often hear from customers. After all, the reason a mechanical room is its own room is because we want all of that heavy equipment and the noise it makes separated from the rest of the home or building. Even so, it can still be loud, even if it’s just one piece of equipment performing its duties without issue.

No matter the size of mechanical rooms, the sound issue is the same. For example, I recently had a customer call who was trying to reduce the sound their well pump was making at their home in the basement. In their residential mechanical room, they had a well pump, a furnace, and a water heater. While the well pump was certainly loud, the rest of that equipment only added to the cacophony, and the house was older with wall assemblies that made it easy for sound to travel. They preferred not to do any renovation, so I steered them toward a set of soundproofing blankets that got the job done.

Each mechanical room situation is unique. They can be found in commercial and residential properties and the latter aren’t always well-chosen within the home. For the above client, it helped that the mechanical room was in the basement and not surrounded by living quarters so that we could take an easier approach to solve the issue. In this article, we’ll look at a large array of mechanical room types and discuss how to soundproof them correctly no matter the circumstance.

Types of Loud Equipment Found in Mechanical Room Situations

Unless you have a well and septic system or work in the mechanical equipment industry, most people aren’t too familiar with mechanical rooms. They are more common than we think in residential homes and always present in commercial buildings. The kinds of noisy equipment found in mechanical rooms include:

HVAC Equipment

HVAC systems include boilers, furnaces, heat pumps, chillers, and air handlers. Any one of these is loud, and the combination can be seriously loud. This also includes ancillary components of the systems such as fans, ductwork, and air filters.

Water Equipment

To distribute and heat water around buildings, mechanical rooms often contain water heaters, pumps, valves, and pipes. Additionally, there may be water softeners, filters, and chemical treatment systems to maintain water quality. In domestic scenarios, this may involve a well pump, too.

Electrical Equipment

Control panels, circuit breakers, transformers, and wiring for powering and controlling various systems are housed in mechanical rooms, and these systems can be significant in size when dealing with large loads, the largest of which are found in the growing array of data centers.

Backup Power Systems

Any large commercial structure will necessitate a backup power system if the grid is unavailable. This is extremely important for healthcare facilities that need the lights on, but also emergency power to be able to operate surgical equipment and continue supplying water and a variety of gases necessary for medical procedures. As battery technology improves, many of these systems rely on batteries – thankfully quiet equipment – but the majority are generators that produce a lot of noise.

Exterior “Mechanical Rooms”

Although not technically mechanical rooms, many builders intelligently place heavy equipment outside so that it doesn’t interfere acoustically with the interior space. This is a great solution for those inside, but it really just moves the sounds to the exterior world, which may also need to be controlled. Banks of air conditioners and generators are commonly placed outside and can readily benefit from soundproofing to limit the noise created.

How to Reduce Sound with Mechanical Room Soundproofing

When we consider soundproofing, what we’re trying to do is block the sound from transmitting from the equipment through the walls of the mechanical room and disturb the rooms beyond. This is made more difficult because the sounds produced by the types of equipment in mechanical rooms are louder than most. We also have to account for the vibrations created by the equipment, to make sure that is not an additional source of noise pollution.

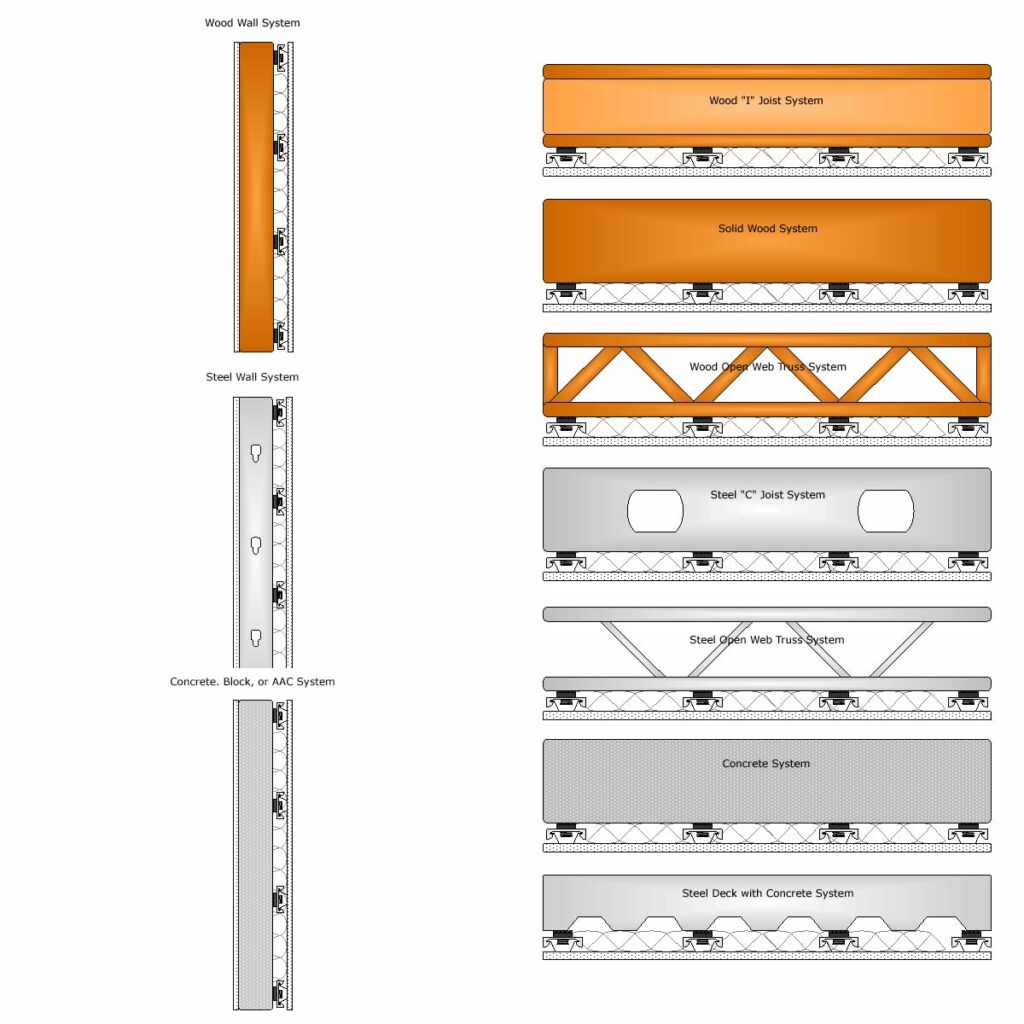

The first step to using mechanical room soundproofing correctly is to understand the wall and ceiling assemblies that make up the room. When analyzing these, we have to understand that mass is extremely helpful in blocking sound. For example, if the ceiling of the mechanical room is concrete as part of a large commercial structure, that’s a high mass material that will already block a good chunk of sound. If the walls are concrete, even better, but typically walls are made with studs and drywall, which if untreated with soundproofing materials, can leak huge amounts of sound.

The ideal soundproofing technique (and my prescription), especially in a commercial environment, is to “beef up” the walls so that they can better block sound. To do this, we need to make the walls more flexible, so that as the sound passes through them, it will progressively lose its energy through dense soundproofing materials and air gaps.

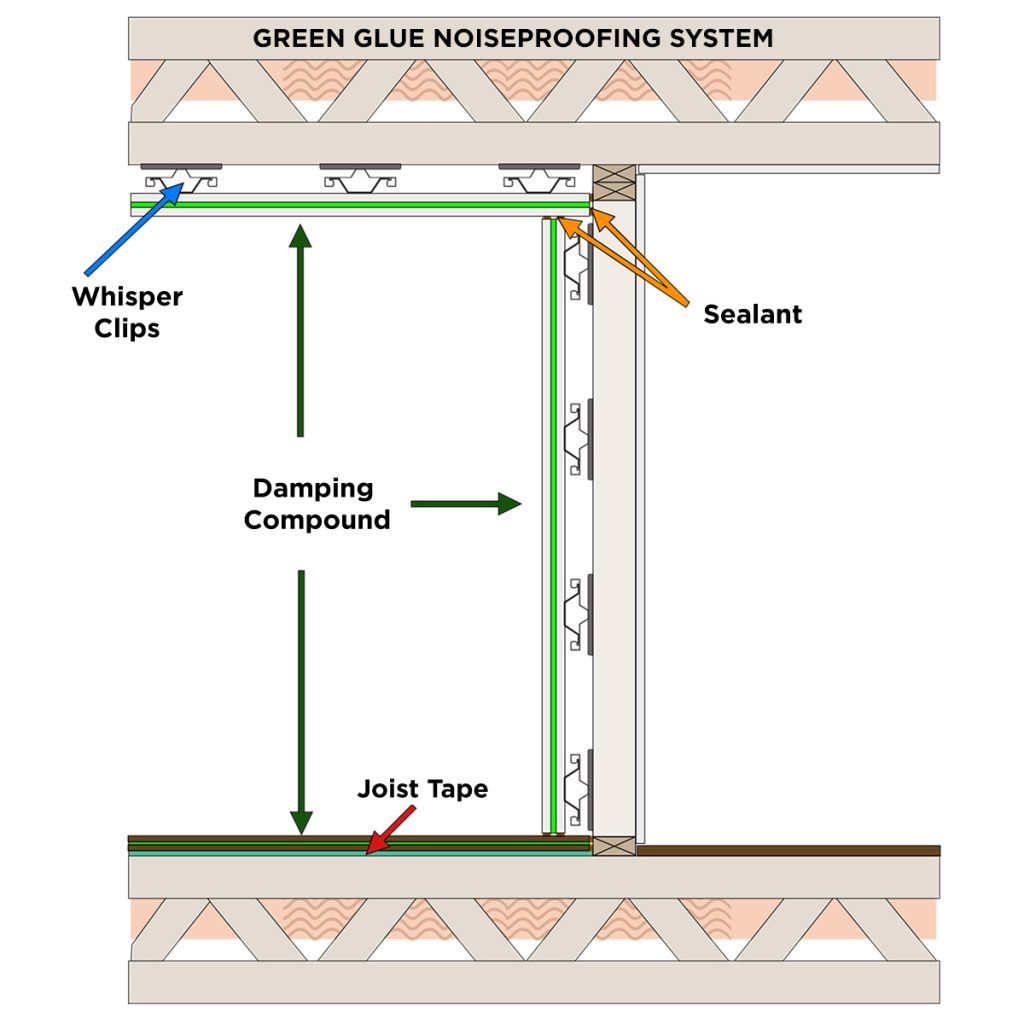

Combining Resilient Sound Isolation Clips (RSIC-1), AudioSeal® Mass Loaded Vinyl (MLV) Soundproofing Barrier, and Green Glue Noiseproofing Compound is a fantastic trio of products to vastly improve the wall assembly’s ability to block sound.

The problem with studs and drywall is that the sound doesn’t have enough medium to travel through in order to lose its energy. Placing AudioSeal® Mass Loaded Vinyl (MLV) Soundproofing Barrier behind drywall begins the improved assembly by adding mass that will slow down the sound. We then apply the Green Glue Noiseproofing Compound to add further mass, and then separate this assembly from the studs with Resilient Sound Isolation Clips (RSIC-1) to create an air gap between the studs, to further sap the sound energy. By the time it travels through the studs to the other side of the wall, the sound has been reduced so much that the rest of the material will take care of the rest of the sound.

The Green Glue Noiseproofing system is designed to work with damping compound, acoustical sealant, Whisper™ Clips and joist tape to provide a complete soundproofing solution.

While this solution is the preferred way, it’s not always the most ideal depending on the circumstances. Sometimes the wall assemblies are already soundproofed well, and they may just need an added boost. This is where I like to rely on soundproofing blankets, such as the one described for the well pump mechanical room. Even in larger applications with heavier equipment, hanging soundproofing blankets can have a dramatic impact on sound transmission. The PrivacyShield® AQFA-11 Industrial Soundproofing Blanket is a fantastic product for this purpose. Depending on the equipment in question, a PrivacyShield® Industrial Sound Enclosure might be the perfect answer if there is one problem child that just needs to be separated individually.

Sound blankets are also a great method to reduce noise pollution in the exterior “mechanical rooms” I mentioned, as you can quickly build an enclosure for your A/C units and/or generators and hang blankets to suppress their sound. For this application, we offer PrivacyShield® ABBC-13DES Designer Colors Barrier Backed Soundproofing Blanket to provide aesthetic options to make sure the outdoor mechanical area looks good and can match the building aesthetics.

A Quick Look at Solving Vibrational Noise

It’s not always just sound that needs to be dealt with from mechanical room equipment, but also the vibrations they create. Typically if equipment is installed properly, modern designs incorporate anti-vibration aspects within the equipment itself. If not, or if you’d like to completely eliminate the possibility of vibrational noise, I suggest installing a VibStop Vibration Damping Sheet for underneath equipment as well as incorporating an Isolation Cup Mount to casters or legs of the equipment, where relevant.

Find the Best Mechanical Room Soundproofing Products From Acoustical Solutions

I really do love soundproofing because of how impactful it can be on the atmosphere of interior environments. Mechanical rooms are often the beating hearts of our structures and we need them, but it would just be great if we could get rid of their noisiness. At Acoustical Solutions, we have a robust soundproofing department that is focused on eliminating mechanical noise from industrial settings to the home mechanical room and seeking out the best products and techniques for our customers.

Give us a call today and I’d be thrilled to discuss the current situation in your mechanical room and develop a plan to keep it going strong but eliminate unwanted noise from the rest of your building or hom

To learn more about how Acoustical Solutions can solve your noise control problems, use our contact form, call one of our Acoustical Sales Consultants at (800) 782-5742, or visit us on the web at acousticalsolutions.com.