Iso-Step® Soundproofing Underlayment

Return Policy: 30% restocking fee within 30 calendar days of invoice date.

Typical Shipping Lead Time: 1–3 weeks

Product Description

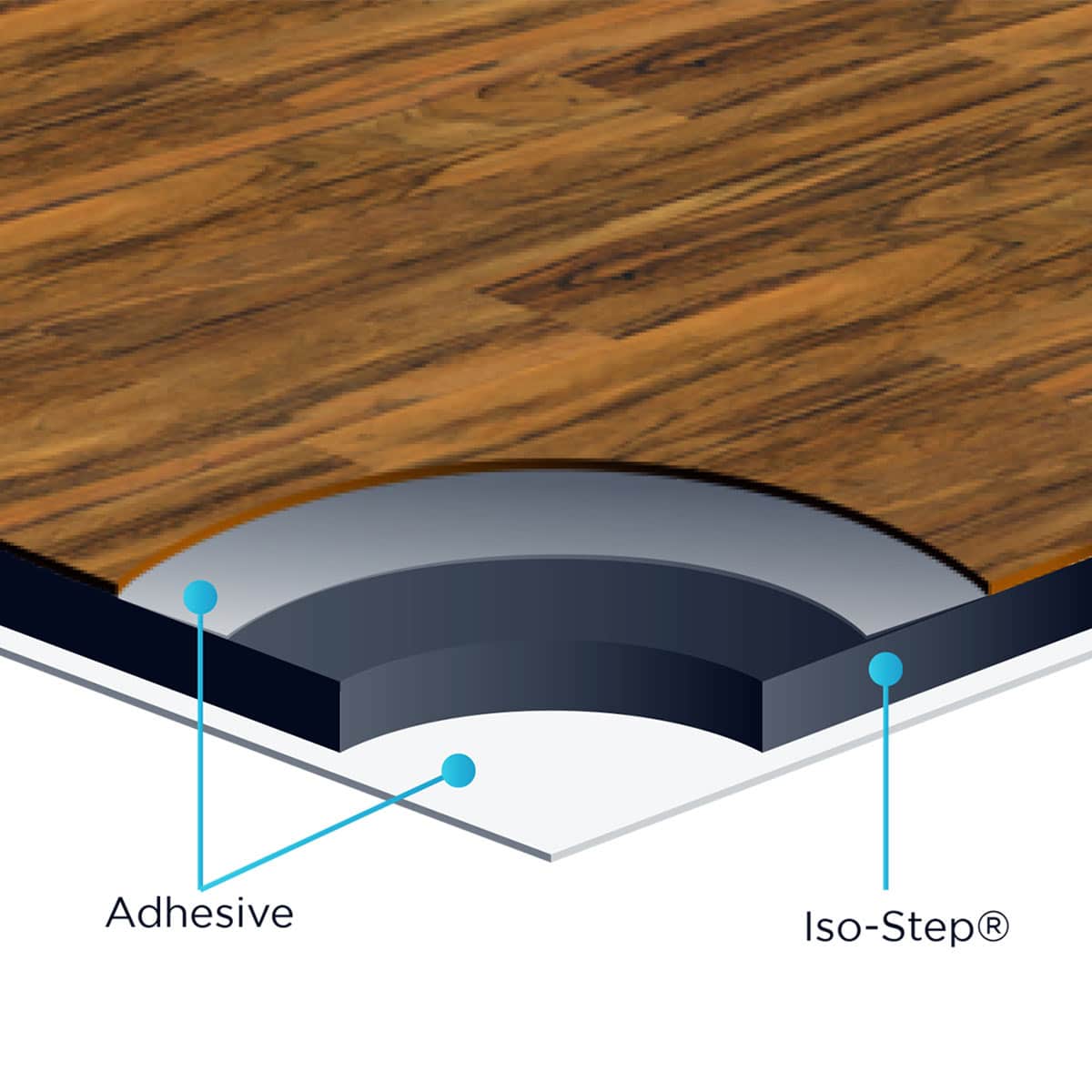

Our Iso-Step® Floor Underlayment is engineered to provide superior impact sound insulation and better performance over other sound control materials. It may be installed over a wood or concrete subfloor and under a wide range of flooring finishes. Installing Iso-Step® underneath the entire flooring assembly short circuits impact noise to combat footfall and structure-borne sound and vibration.

Impact noise is a structure-borne sound created when two objects collide. This impact energy creates vibrations that resonate through the materials in the structure. It also creates airborne sound. This is often realized in the real world as a ‘neighbor noise’ generated from someone walking on the floor above or other activities. The Iso-Step® acoustic floor underlayment should be placed underneath the finished flooring and cover the whole floor. This provides an isolation layer to help prevent structural sound from passing through the completed assembly.

Manufactured in the USA using recycled material, this rubber floor underlayment has been rigorously field tested with proven results. It can be installed under most types of grouted, glued, and floating floors, including ceramic tile, stone, marble, brick, pavers, hardwood, engineered wood, laminate, parquet, luxury vinyl tile, and carpet.

Our Iso-Step® Floor Underlayment is available in thicknesses of 2 mm, 5mm, 6mm, 10 mm, and 12 mm. With a Delta IIC from 22 to 25, we offer a rubber floor underlayment well-suited to meet any job requirement.

We recommend using Iso-Step® Soundproofing Underlayment Adhesive or Iso-Step® Quick Cure Soundproofing Underlayment Adhesive with this product.

Features

- Fast installation

- Compatible with most floor finishes

- Manufactured from recycled rubber

- Can thin-set tile and stone direct to product per ASTM C627

- Rated extra heavy by the Tile Council of North America

- Passes VOC Washington State IAQ Test (ASTM D5116)

- 94% post-consumer recycled content

- Made in the USA

Technical Information for Iso-Step® Floor Underlayment

- Thickness: 2 mm, 5 mm, 6mm, 10 mm, 12 mm

- Roll Size: 48″ x 75′ (2 mm), 48″ x 30′ (5 mm, 6mm), 48″ x 15′ (10 mm), 48″ x 15′ (12 mm)

- Roll Weight: 141 lbs. (2mm), 120 lbs. (5 mm), 144 lbs. (6mm), 120 lbs. (10mm), 150 lbs. (12 mm)

- Material: 92% resilient recycled rubber

- Physical Data

- Density: 0.72 g/ cubic cm min. (ASTM D297)

- Tensile Strength: 80 psi, min. (ASTM D412, Die C)

- Tear Strength: 30 ppi, min. (ASTM D624)

- Elongation: 50%, min. (ASTM D412, Die C)

- Compression: 20-30%, 85%, min. (at 100 psi recovery)

- Shore A Hardness: 40 durometer (ASTMD2240)

- Flexibility: 1 factor, max. (ASTM F147)

- Compression Set B, 25% Deflection, 158 degrees/22 hrs: 40% Max (ASTM D395)

- Coefficient of Friction: 1.2 (ASTM D1894)

- Crack Resistance: High Performance (ASTM 118.12 5.4)

- Tolerance:

- Width: +3/4″ – 0″

- Length: +1% – 0″

- Thickness: +/- 0.3 mm

- Installation: Refer to installation guides posted in the documents tab.

Common Assemblies STC/IIC Ratings

| Iso-Step Common Commercial Assemblies | |||||

| Finished Floor | Underlayment | Base Assembly | Ceiling | Total Assembly STC/IIC | STC/IIC |

| Ceramic Tile | 2mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 61/52 | 32 |

| Engineered Wood | 2mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 59/55 | 24 |

| 5mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/55 | 32 | |

| 6mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/55 | 27 | |

| 10mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/56 | 32 | |

| 12mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/56 | 27 | |

| Click-Lock LVT | 2mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/53 | 31 |

| 5mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 61/54 | 31 | |

| 6mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/54 | 26 | |

| 10mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/55 | 30 | |

| 12mm Iso-step | 3/4″ Gypsum Concrete over OSB on 18″ Open Web Truss | R-13 Insulation, RC Deluxe (16″ o.c.), 1 Layer Type C Drywall | 60/55 | 26 | |

| Iso-Step Common Commercial Assemblies | |||||

| Finished Floor | Underlayment | Base Assembly | Ceiling | Total Assembly STC/IIC | HIIC |

| Ceramic Tile | 2mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/59 | 58 |

| Engineered Wood | 2mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 60/64 | 66 |

| 5mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/64 | 69 | |

| 6mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/64 | 69 | |

| 10mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 62/66 | 76 | |

| 12mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/64 | 72 | |

| Click-Lock LVT | 2mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 60/66 | 69 |

| 5mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/66 | 73 | |

| 6mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 60/66 | 75 | |

| 10mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/67 | 77 | |

| 12mm Iso-step | 6" Concrete | Yes/Wire Hung Ceiling With R-13, 1 Layer Type X Drywall | 61/65 | 74 | |

| Iso-Step Wood Floor Assemblies | |||||

| Finished Floor | Underlayment | Base Assembly | Ceiling | Total Assembly STC/IIC | HIIC |

| Ceramic Tile | 2mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 61/52 | 55 |

| Engineered Wood | 2mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 59/55 | 68 |

| 5mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/55 | 68 | |

| 6mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/55 | 69 | |

| 10mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/56 | 70 | |

| 12mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/56 | 70 | |

| Click-Lock LVT | 2mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/53 | 65 |

| 5mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 61/54 | 70 | |

| 6mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/54 | 70 | |

| 10mm Iso-step | 3/4" OSB on 18" Open Web Truss |

R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/55 | 72 | |

| 12mm Iso-step | 3/4" OSB on 18" Open Web Truss | R-13 Insulation, RC Deluxe (16" o.c.), 1 Layer Type C Drywall | 60/55 | 72 | |

Frequently Asked Questions

Iso-Step® is used to prevent impact and structural borne sound from passing through construction assemblies. The IIC (Impact Insulation Class) ratings directly relate to the measure of impact reduction. STC (Sound Transmission Class) ratings are used to quantify how much airborne sound is reduced by a material or construction assembly. Iso-Step® is not intended to reduce airborne sound. However, the overall construction assembly, which includes Iso-Step®, would have an improved STC value. It is the complete assembly that provides a reduction in airborne sound. The overall assembly would be tested to determine an STC value.

- STC (Sound Transmission Class) Quantifies the performance of a material or partition to attenuate airborne sound. This roughly reflects the decibel reduction of a building material or partition. Higher Numbers = Higher Performance.

- IIC (Impact Insulation Class): Impact insulation class (IIC) is a number rating of how well a building material or construction assembly attenuates impact sounds, such as footsteps. A larger number means more attenuation.

At no point should nails penetrate the Iso-Step® floor underlayment layer and make contact with the sub-floor. This would ‘short-circuit’ the flooring assembly and allow sound and vibration to transfer to the underlying construction assembly.

The nail-down flooring should be nailed to an additional subfloor layer. The subfloor layer should be thick enough so that nails do not protrude. The Iso-Step® flooring underlayment would reside under this layer, free from any penetrating nails.